WORKING AT HEIGHTS

2013

Bachelor Thesis

Industrial Design

Context

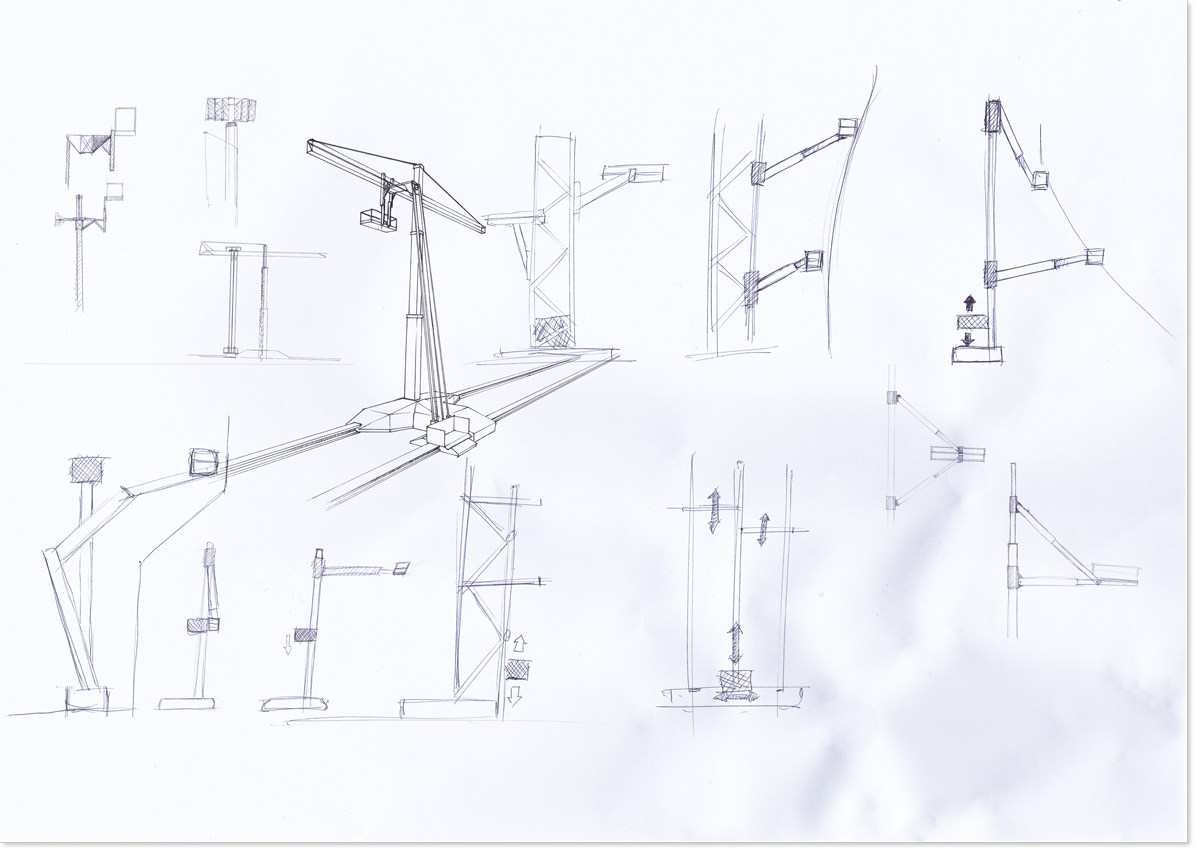

How can manual work at height be designed to be easier, safer and more efficient? Is it possible to influence this through the rethinking of workflows?

The assembly and disassembly of scaffoldings is one of the most physically demanding and dangerous tasks at construction sites. Manual work in areas that are difficult to access may be considered challenging from various standpoints.

The most common challenges are the transport of material, as well as the planning and organising of workflows.

Coordinated Workflow 1800

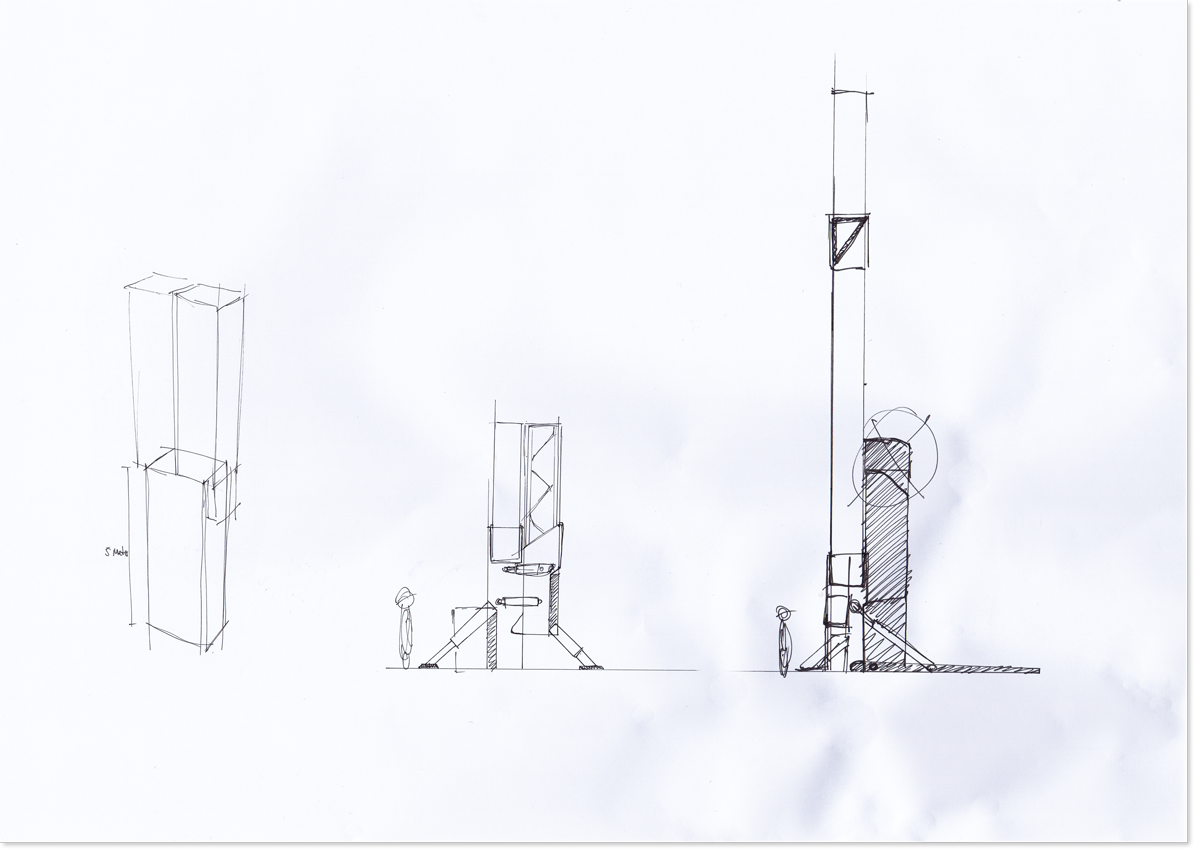

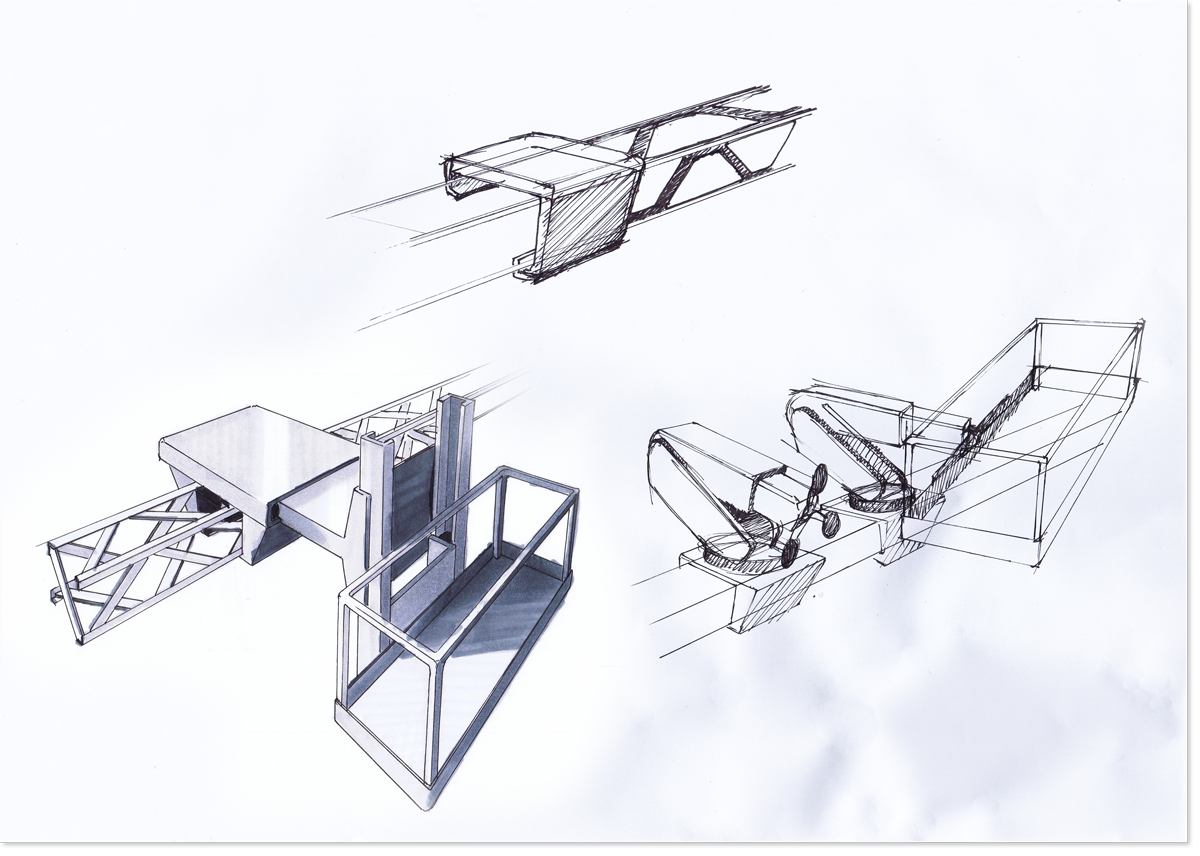

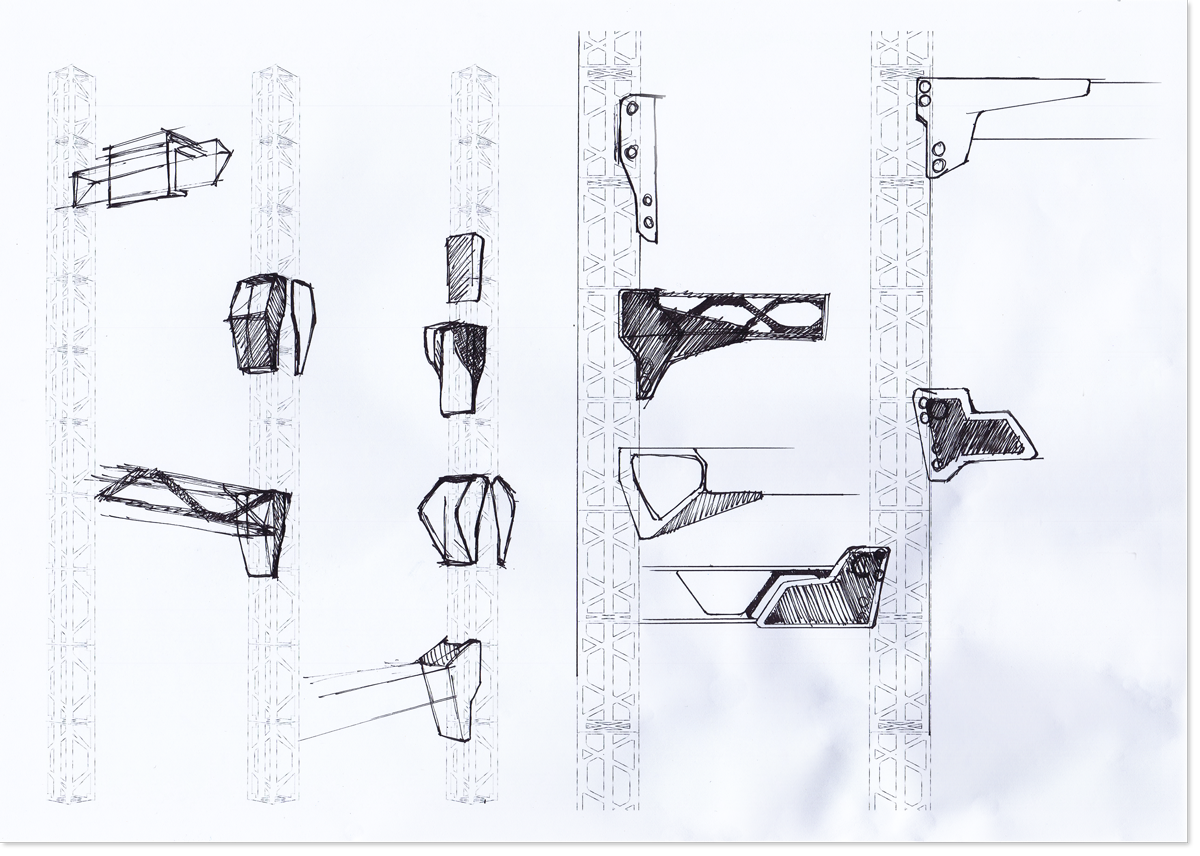

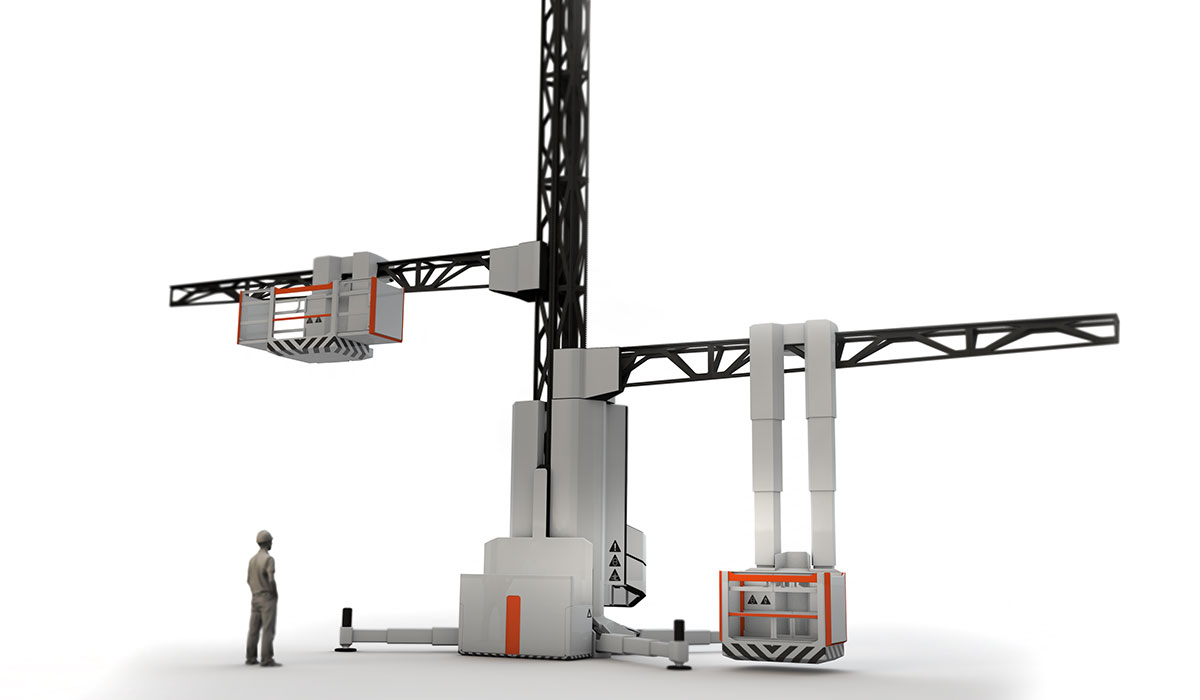

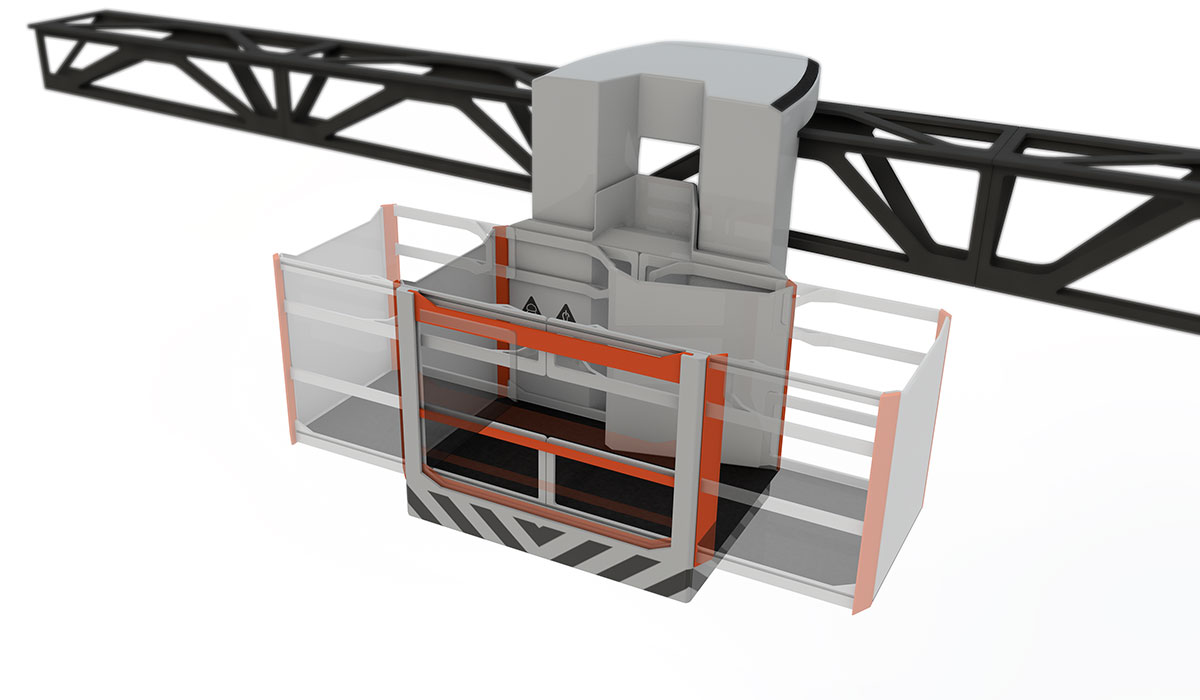

The concept shows, that established workflows and methods in manual labour may be reconsidered with a more human-centred approach to design. Through a fast and secure assembly- and disassembly process, through thought-out workflows and a constant flow of material a higher work efficiency can be achieved.

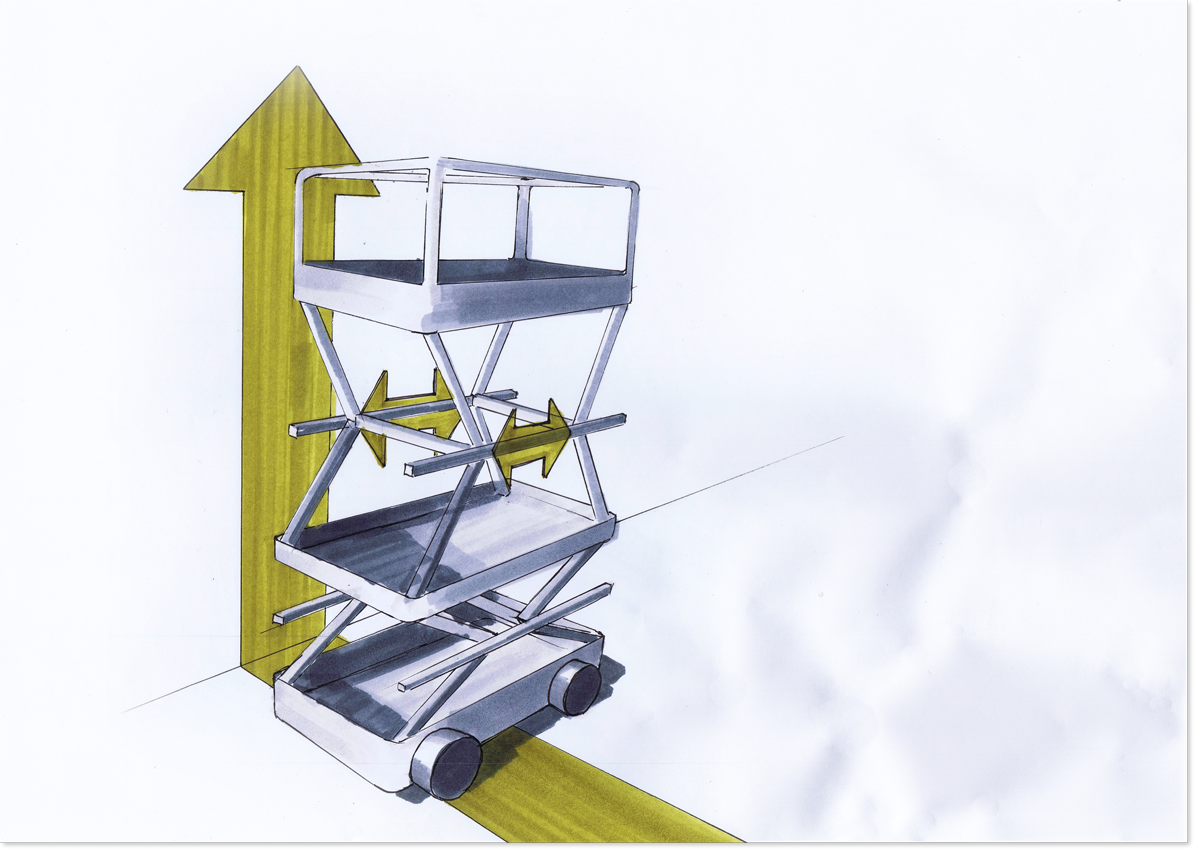

Coordinated Workflow 1800 is a work unit for facades, that in its basic setup can reach a height and span of 18 meters. It is a tool which is integrated into workflows. Pre-planned steps may be handled in stages, and hereby be accomplished faster and with less strain. A material lift connects the ground floor and working cages through the vertical supporting column, thus maintaining a centralised material flow. In contrary to conventional scaffoldings this concept blends with the urban environment.